Nozzles

|

I. Description

II. Types

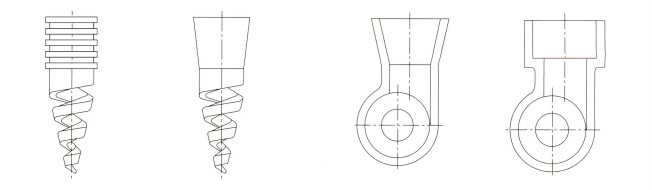

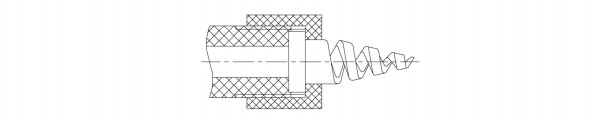

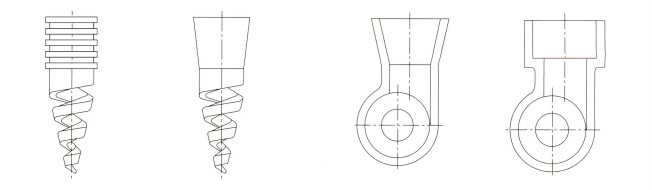

I. A screw-type nozzle

A screw-type nozzle can be divided into A1 solid nozzle and A2 hollow nozzle according to fog crown.

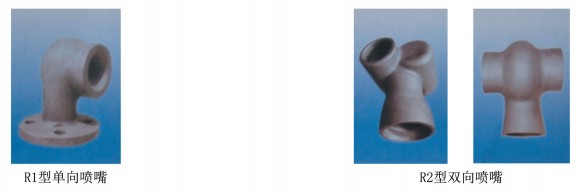

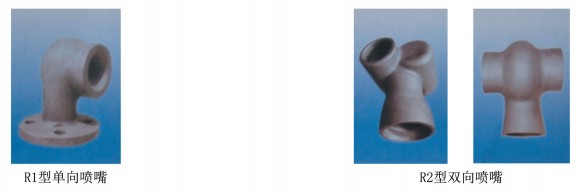

II. R hollow linear nozzle

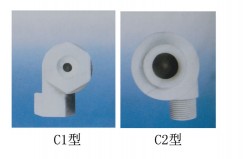

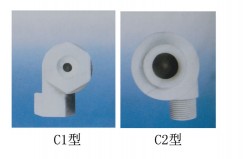

III. C tobacco pipe type nozzle

C tobacco pipe type nozzle can be divided into C1 and C2 two types.

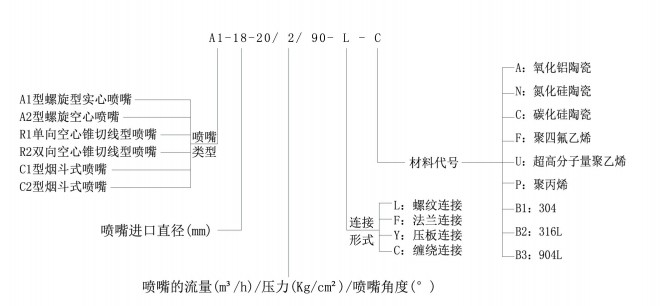

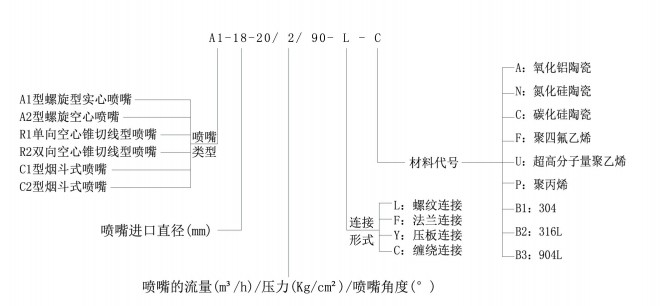

III. Demonstration of model

IV. Materials

Nozzles materials: 1. silicon carbide SiC (code C) 2. Silicon nitride Si3N4 (code N) 3. Aluminium oxide Al2O3 (code A) 4. Ultra-high molecular weight polyethylene UHPE (code U) 5. Polytetrafluoroethylene F4 (code F) 6. Polypropylene PP (code P) 7. 304 (code B1) 8.316L (code B2) 9.904L (code B3)

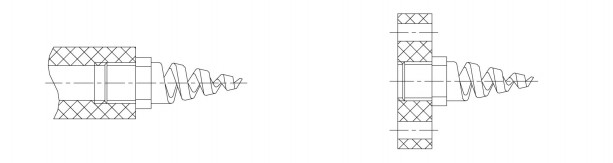

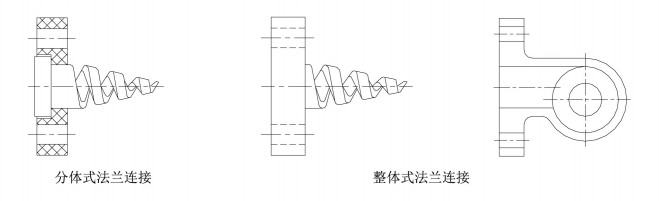

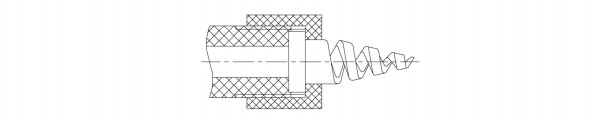

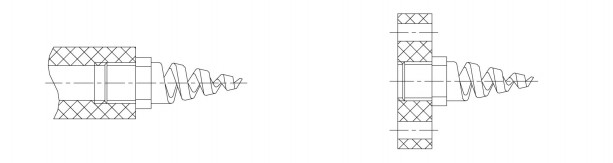

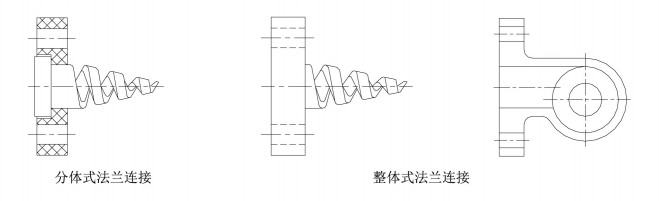

V. Type of connection

Four types: screw type (code L), flange type (code F), pressing plate type (code Y), winding type (code C)

VI. Performance parameters

| I. A screw type connection |

| Inlet diameter |

Spray angle (°) |

Quantity of flow (m3/h) at various pressures (kg/cm2) |

Thread size |

| mm |

60 |

90 |

120 |

0.5 |

0.7 |

1 |

2 |

3 |

|

| 2.4 |

· |

· |

· |

0.14 |

0.16 |

0.19 |

0.27 |

0.33 |

G1/4" |

| 3.2 |

· |

· |

· |

0.25 |

0.3 |

0.36 |

0.5 |

0.62 |

(external diameter Ф13.2) |

| 4 |

· |

· |

· |

0.39 |

0.46 |

0.55 |

0.77 |

0.95 |

|

| 4.8 |

· |

· |

· |

0.58 |

0.69 |

0.82 |

1.16 |

1.42 |

G3/8" |

| 5.6 |

· |

· |

· |

0.79 |

0.93 |

1.11 |

1.57 |

1.92 |

(external diameter Ф16.7) |

| 6.4 |

· |

· |

· |

1.03 |

1.21 |

1.45 |

2.05 |

2.51 |

|

| 7.9 |

· |

· |

· |

1.6 |

1.89 |

2.26 |

3.19 |

3.91 |

G1/2" (external diameter Ф21) |

| 9.6 |

· |

· |

· |

2.33 |

2.75 |

3.29 |

4.66 |

5.71 |

| 11.1 |

· |

· |

· |

3.19 |

3.77 |

4.51 |

6.36 |

7.8 |

| 12.7 |

· |

· |

· |

4.06 |

4.81 |

5.74 |

8.1 |

9.96 |

G3/4" |

| 15.9 |

· |

· |

· |

6.48 |

7.68 |

9.18 |

12.96 |

15.9 |

(external diameter Ф26.4) |

| 19.1 |

· |

· |

· |

9.18 |

10.86 |

12.96 |

18.3 |

22.44 |

G1" |

| 22.2 |

· |

· |

· |

12.48 |

14.76 |

17.64 |

24.96 |

30.54 |

(external diameter Ф33.2) |

| 25.4 |

· |

· |

· |

16.32 |

19.32 |

23.1 |

32.64 |

40.02 |

G1 1/2" (external diameter Ф47.8) |

| 28.6 |

· |

· |

· |

18.18 |

21.48 |

25.68 |

36.3 |

44.46 |

| 34.9 |

· |

· |

· |

27.06 |

32.04 |

38.28 |

54.12 |

66.3 |

| 38.1 |

· |

· |

· |

34.2 |

40.44 |

48.36 |

68.4 |

83.76 |

G2" |

| 44.5 |

· |

· |

· |

49.62 |

58.74 |

70.2 |

99.3 |

121.56 |

(external diameter Ф59.6) |

| 50.8 |

· |

· |

· |

65.76 |

77.82 |

93 |

131.52 |

161.1 |

G3" |

| 63.5 |

· |

· |

· |

101.4 |

120 |

143.4 |

202.8 |

248.4 |

(external diameter Ф87.9) |

| |

|

|

|

|

|

|

|

|

|

| |

| II. R hollow linear nozzle |

| Inlet diameter |

Quantity of flow (m3h) at various pressures (kg/cm2) |

Spray orifice diameter |

Spray angle (°) at various pressures (kg/cm2) |

| |

|

| mm |

0.2 |

0.3 |

0.5 |

0.7 |

1 |

1.5 |

2 |

3 |

mm |

0.5 |

1.5 |

3 |

| 17.5 |

1.44 |

1.8 |

2.28 |

2.7 |

3.24 |

3.96 |

4.56 |

5.64 |

15.5 |

67 |

69 |

71 |

| 1.74 |

2.16 |

2.76 |

3.24 |

3.9 |

4.8 |

5.52 |

6.78 |

17.1 |

70 |

73 |

75 |

| 2.22 |

2.7 |

3.48 |

4.14 |

4.92 |

6 |

6.96 |

8.52 |

20.6 |

76 |

79 |

81 |

| 24.1 |

2.34 |

2.88 |

3.72 |

4.38 |

5.22 |

6.42 |

7.38 |

9.06 |

20.2 |

74 |

75 |

77 |

| 2.94 |

3.6 |

4.62 |

5.46 |

6.54 |

7.98 |

9.24 |

11.34 |

24.2 |

76 |

77 |

79 |

| 27.8 |

3.66 |

4.44 |

5.76 |

6.84 |

8.16 |

10.02 |

11.52 |

14.16 |

25.8 |

72 |

74 |

76 |

| 4.38 |

5.34 |

6.9 |

8.16 |

9.78 |

12 |

13.86 |

16.92 |

28.6 |

74 |

76 |

78 |

| 36.5 |

5.1 |

6.3 |

8.1 |

9.6 |

11.46 |

14.04 |

16.2 |

19.86 |

27 |

68 |

70 |

73 |

| 5.88 |

7.2 |

9.36 |

11.04 |

13.2 |

16.14 |

18.66 |

22.86 |

30.2 |

70 |

72 |

75 |

| 6.6 |

8.04 |

10.38 |

12.3 |

14.7 |

18 |

20.76 |

25.44 |

32.9 |

72 |

74 |

78 |

| 7.26 |

8.88 |

11.46 |

13.56 |

16.2 |

19.86 |

22.92 |

28.08 |

36.1 |

74 |

77 |

82 |

| 8.7 |

10.68 |

13.8 |

16.32 |

19.5 |

23.88 |

27.6 |

33.78 |

39.7 |

77 |

79 |

84 |

| 47.6 |

10.2 |

12.48 |

16.14 |

19.08 |

22.8 |

27.9 |

32.22 |

39.48 |

40.5 |

69 |

71 |

74 |

| 11.7 |

14.28 |

18.48 |

21.84 |

26.1 |

31.98 |

36.9 |

45.18 |

44.1 |

71 |

73 |

77 |

| 13.14 |

16.08 |

20.76 |

24.6 |

29.4 |

36 |

41.58 |

50.94 |

47.6 |

73 |

77 |

80 |

| 14.46 |

17.76 |

22.92 |

27.12 |

32.4 |

39.66 |

45.84 |

56.1 |

50.8 |

77 |

79 |

83 |

| 57.2 |

17.46 |

21.36 |

27.6 |

32.64 |

39 |

47.76 |

55.14 |

67.56 |

52.4 |

71 |

73 |

77 |

| 20.4 |

24.96 |

32.22 |

38.16 |

45.6 |

55.86 |

64.5 |

78.96 |

58.7 |

73 |

75 |

80 |

| 79.4 |

22.02 |

26.94 |

34.8 |

41.16 |

49.2 |

60.24 |

69.6 |

85.2 |

50.8 |

66 |

67 |

70 |

| 25.5 |

31.2 |

40.32 |

47.7 |

57 |

69.84 |

80.58 |

98.7 |

59.1 |

68 |

70 |

71 |

| 29.22 |

35.82 |

46.26 |

54.72 |

65.4 |

80.1 |

92.46 |

113.28 |

68.3 |

70 |

72 |

74 |

| 33 |

40.44 |

52.2 |

61.74 |

73.8 |

90.36 |

104.34 |

127.8 |

74.6 |

72 |

74 |

77 |

| 36.48 |

44.7 |

57.72 |

68.28 |

81.6 |

99.96 |

115.38 |

141.36 |

82.6 |

74 |

76 |

81 |

| 40.26 |

49.32 |

63.66 |

75.3 |

90 |

110.22 |

127.26 |

155.88 |

92.1 |

78 |

80 |

83 |

| 124 |

43.74 |

53.58 |

69.18 |

81.84 |

97.8 |

119.76 |

138.3 |

169.38 |

69.9 |

66 |

68 |

70 |

| 51.24 |

62.76 |

81.06 |

95.88 |

114.6 |

140.34 |

162.06 |

198.48 |

76.2 |

68 |

70 |

72 |

| 58.5 |

71.64 |

92.46 |

109.44 |

130.8 |

160.2 |

184.98 |

226.56 |

82.6 |

70 |

73 |

75 |

| 65.76 |

80.52 |

103.92 |

123 |

147 |

180.06 |

207.9 |

254.58 |

88.1 |

72 |

75 |

77 |

| 72.96 |

89.4 |

115.38 |

136.56 |

163.2 |

199.86 |

230.82 |

282.66 |

97.2 |

74 |

76 |

79 |

| 80.52 |

98.58 |

127.26 |

150.6 |

180 |

220.44 |

254.58 |

311.76 |

108 |

76 |

79 |

83 |

| 91.5 |

112.08 |

144.66 |

171.18 |

204.6 |

250.56 |

289.32 |

354.36 |

130 |

78 |

81 |

86 |

| |

|

|

|

|

|

|

|

|

|

|

|

|

| |

| III. C1 tobacco pipe type nozzle |

Work condition

Technical param

- eters

Specifi

- cation |

Working pressure 0.2MPa |

Working pressure 0.3MPa |

Working pressure 0.4MPa |

Install

- ation dimen

- sion |

Quan

- tity

of

flow |

Fog

crown diam

- eter |

Spray angle |

Spray |

Quantity of flow |

Fog crown diameter |

Spray angle |

Spray |

Quan

- tity

of

flow |

Fog

crown diam

- eter |

Spray angle |

Spray |

G" |

| m3/h |

m |

° |

|

m3/h |

m |

° |

|

m3/h |

m |

° |

|

| Ф3 |

0.25 |

1.5 |

80 |

common |

0.35 |

1.6 |

90 |

favorable |

0.45 |

2 |

100 |

Good |

G1/2 |

| Ф4 |

0.4 |

1.5 |

80 |

common |

0.5 |

1.8 |

90 |

favorable |

0.6 |

2.5 |

100 |

Good |

G1/2 |

| Ф5 |

0.5 |

1.5 |

80 |

common |

0.65 |

2 |

90 |

favorable |

0.8 |

2.6 |

100 |

Good |

G1/2 |

| Ф6 |

0.6 |

1.6 |

80 |

common |

0.75 |

2 |

90 |

favorable |

0.9 |

2.6 |

100 |

Good |

G1/2 |

| Ф7 |

0.85 |

1.6 |

80 |

common |

1 |

2 |

90 |

favorable |

1.25 |

2.6 |

100 |

Good |

G1/2 |

| Ф8 |

0.92 |

1.7 |

80 |

common |

1.15 |

2 |

90 |

favorable |

1.35 |

2.6 |

100 |

Good |

G1/2 |

| Ф10 |

1.2 |

1.8 |

80 |

common |

1.5 |

2.3 |

90 |

favorable |

1.75 |

2.8 |

100 |

Good |

G1/2 |

| Ф12 |

1.5 |

2 |

80 |

common |

1.85 |

2.5 |

90 |

favorable |

2.25 |

3 |

100 |

Good |

G1/2 |

| IV. C2 tobacco pipe type nozzle |

Working condition

Technical param

- eters

Specifi

- cation |

Working pressure 0.2MPa |

Working pressure 0.3MPa |

Working pressure 0.4MPa |

Install

- ation dimen

- sion |

| Quantity of flow |

Fog crown diameter |

Spray angle |

Spray |

Quantity of flow |

Fog crown diameter |

Spray angle |

Spray |

Quantity of flow |

Fog crown diameter |

Spray angle |

Spray |

G" |

| m3/h |

m |

° |

|

m3/h |

m |

° |

|

m3/h |

m |

° |

|

| Ф16 |

2.85 |

2.5 |

100 |

common |

3 |

2.8 |

100 |

Good |

3.5 |

3 |

100 |

Good |

G3/4 |

| Ф20 |

5.5 |

2.5 |

100 |

common |

7 |

2.8 |

90 |

Good |

8.5 |

3 |

100 |

Good |

G3/4 |

| Ф25 |

12 |

2.5 |

100 |

common |

14 |

2.8 |

90 |

Good |

17 |

3 |

100 |

Good |

G1 |

|

Performance curve

Performance parameters

Structure description

Pre: FFU engineering plastic float pump

Next: Composite metal plastic pipe and pipe fitting