Engineering plastic diaphragm valve, ball valve, butterfly valve, bottom valve and compensator

|

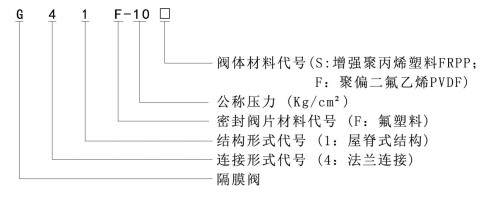

I. Description Our G41F-10S, G41F-10F reinforced PP, PVDF diaphragm valves have features such as no toxicity, no odor, light weight, good corrosion resistance, good sealing property, attractive appearance, flexible open, etc. II. Demonstration of model

III. Materials of main parts

IV. Applicable temperature

V. Overall dimensions and installation dimension

I. Description Our plastic ball valve can be widely used in chemical, chemical fiber, environmental protection, pharmaceutical, metallurgy, papermaking, printing and dyeing, textile, food and other industries. II. Demonstration of model

III. Materials of main parts

IV. Applicable temperature

V. Overall dimensions and installation dimension

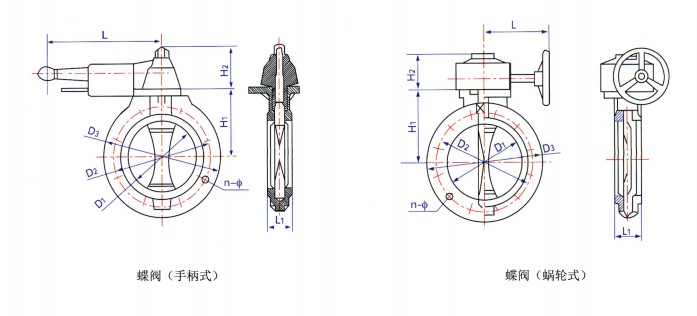

I. Description The product has advantages such as light weight, small hydraulic resistance, convenient disassembly, etc. It is suitable for gas, liquid and other corrosive media. II. Demonstration of model

III. Materials of main parts

IV. Overall dimensions and installation dimension D71X-6S、D71X-6F handle type butteryfly valve |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Nominal diameter (DN) | Overall dimensions and installation dimension (mm) | Working pressure (MPa) | Weight (Kg) | Operation | Working temperature ℃ | ||||||||

| D1 | D2 | D3 | L | L1 | H1 | H2 | n-Ф | FRPP | FVDF | handle type | |||

| 40 | 47 | 110 | 150 | 200 | 39 | 86 | 70 | 4-18 | 0.7 | 1.2 | 1.5 | ||

| 50 | 56 | 125 | 160 | 220 | 40 | 88 | 70 | 4-18 | 0.7 | 1.3 | 1.6 | FRPP | |

| 65 | 71 | 145 | 185 | 220 | 46 | 100 | 70 | 4-18 | 0.7 | 1.7 | 2 | -14℃~100℃ | |

| 80 | 85 | 160 | 195 | 280 | 46 | 105 | 85 | 8-18 | 0.7 | 2.3 | 2.7 | PVDF | |

| 100 | 105 | 180 | 215 | 280 | 54 | 118 | 85 | 8-18 | 0.6 | 4 | 4.8 | -40℃~+135℃ | |

| 125 | 131 | 210 | 250 | 300 | 70 | 163 | 93 | 8-18 | 0.5 | 4.8 | 5.7 | ||

| 150 | 153 | 240 | 285 | 300 | 74 | 176 | 93 | 8-22 | 0.5 | 5.5 | 6.5 | ||

D371X-6S D371X-6Fworm gear butterfly bamper

| Nominal diameter (DN) | Overall dimensions and installation dimension (mm) | Working pressure (MPa) | Weight (Kg) | Operation | Working temperature ℃ | ||||||||

| D1 | D2 | D3 | L | L1 | H1 | H2 | n-Ф | FRPP | FVDF | worm gear type | |||

| 125 | 131 | 210 | 250 | 300 | 70 | 163 | 93 | 8-18 | 0.5 | 4.8 | 5.7 | ||

| 150 | 153 | 240 | 285 | 300 | 74 | 176 | 93 | 8-22 | 0.5 | 5.5 | 6.5 | ||

| 200 | 204 | 295 | 340 | 180 | 87 | 210 | 93 | 12-22 | 0.4 | 19 | 22 | FRPP | |

| 250 | 255 | 350 | 395 | 180 | 114 | 240 | 93 | 12-22 | 0.3 | 28 | 32 | -14℃~100℃ | |

| 300 | 307 | 400 | 445 | 180 | 114 | 270 | 93 | 12-22 | 0.3 | 34 | 39 | PVDF | |

| 350 | 358 | 460 | 505 | 180 | 127 | 300 | 93 | 16-22 | 0.3 | 52 | 59 | -40℃~+135℃ | |

| 400 | 389 | 515 | 580 | 240 | 140 | 350 | 108 | 16-22 | 0.3 | 78 | 89 | ||

| 450 | 446 | 565 | 615 | 240 | 152 | 370 | 108 | 20-26 | 0.2 | 76 | 84 | ||

| 500 | 494 | 620 | 670 | 260 | 152 | 400 | 108 | 20-26 | 0.2 | 84 | 96 | ||

| 600 | 590 | 725 | 780 | 260 | 178 | 465 | 108 | 20-30 | 0.2 | 105 | 112 | ||

.jpg)

I. Description

Bottom valve is also known as check valve. It is manufactured with corrosion resistant material FRPP or UHMWPE, thus it has good corrosion resistance.

II. Demonstration of model

.jpg)

III. Materials of main parts

| Material | Medium temperature℃ |

| FRPP | -14℃~+100℃ |

| UHMWPE | -50℃~+100℃ |

.jpg)

IV. Overall dimensions and installation dimension

| Nominal diameter (DN) | Overall dimensions and installation dimension (mm) | |||||

| D1 | D2 | D3 | d | n | L | |

| 32 | 32 | 100 | 135 | 18 | 4 | 160 |

| 40 | 40 | 110 | 145 | 18 | 4 | 160 |

| 50 | 50 | 125 | 160 | 18 | 4 | 200 |

| 65 | 65 | 145 | 180 | 18 | 4 | 220 |

| 80 | 80 | 160 | 195 | 18 | 4 | 270 |

| 100 | 100 | 180 | 215 | 18 | 8 | 370 |

| 125 | 125 | 210 | 260 | 18 | 8 | 450 |

| 150 | 150 | 240 | 280 | 23 | 8 | 430 |

| 200 | 200 | 295 | 335 | 23 | 8 | 650 |

| 250 | 250 | 350 | 390 | 23 | 12 | 750 |

| 300 | 300 | 400 | 440 | 23 | 12 | 910 |

.jpg)

I. Description

F4 corrugated pipeline compensator can be used in pump, pipe, valve, and section.

II. Materials of main parts

| Name | Material |

| Fusible screw | Stainless steel |

| Connecting flange | Q235-A |

| Bellows | F4 |

| Safety loop | Stainless steel |

III. Adaptive temperature range

| Material | Medium temperature ℃ |

| F4 | -10~+150℃ |

.jpg)

IV. Overall dimensions and installation dimension

| Nominal diameter | L | Safe expansion | Ripple number | F4 | Reinforcing ring stainless steel wire | Flange (10kg/cm2) | |||

| (DN) | Thickness | Diameter | D | Thickness | d | n | |||

| 25 | 90 | 15 | 4 | 2 | 3 | 85 | 14 | 14 | 4 |

| 32 | 90 | 15 | 4 | 2 | 3 | 100 | 16 | 18 | 4 |

| 40 | 90 | 15 | 4 | 2.5 | 3 | 110 | 18 | 18 | 4 |

| 50 | 90 | 15 | 3 | 2.5 | 3 | 125 | 18 | 18 | 4 |

| 65 | 100 | 15 | 3 | 2.5 | 3 | 145 | 20 | 18 | 4 |

| 80 | 100 | 20 | 3 | 2.8 | 4 | 160 | 20 | 18 | 8 |

| 100 | 120 | 20 | 3 | 2.8 | 5 | 180 | 22 | 18 | 8 |

| 125 | 130 | 20 | 3 | 2.8 | 6 | 210 | 24 | 18 | 8 |

| 150 | 150 | 20 | 3 | 2.8 | 6 | 240 | 24 | 18 | 8 |

| 200 | 150 | 20 | 3 | 2.8 | 6 | 295 | 24 | 23 | 12 |

| 250 | 160 | 20 | 3 | 2.8 | 6 | 350 | 26 | 23 | 12 |

| 300 | 160 | 20 | 3 | 2.8 | 6 | 400 | 28 | 23 | 12 |

| 350 | 160 | 20 | 3 | 2.8 | 6 | 460 | 28 | 23 | 16 |

| 400 | 180 | 20 | 3 | 2.8 | 6 | 515 | 30 | 25 | 16 |

| 450 | 180 | 20 | 3 | 2.8 | 6 | 565 | 30 | 25 | 20 |

| 500 | 200 | 20 | 3 | 2.8 | 6 | 620 | 32 | 25 | 20 |

| 600 | 200 | 20 | 3 | 2.8 | 6 | 725 | 36 | 30 | 20 |

Performance curve

Performance parameters

Structure description

Pre: Composite metal plastic pipe and pipe fitting

Next: None

.jpg)

.jpg)

.jpg)

.jpg)