FCU engineering plastic side suction pump

|

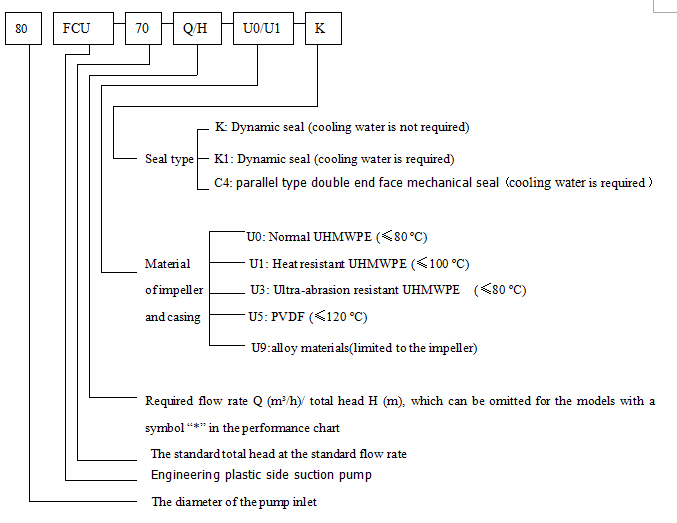

I. General introduction FCU series engineering plastic corrosion resistant side suction pump is to use the company the original FLU series engineering plastic filter pump hydraulic model, combined with the characteristics of the working conditions of filter press carefully designed a specially designed for press filter matching the corrosion wear resistance of high lift side suction horizontal centrifugal pumps, its main characteristics are as follows: II. Application Because of its unique side suction type design, FCU series engineering plastic corrosion resistant side suction pump especially suitable for non-ferrous smelting industry in particular, lead, zinc, gold, silver, copper, cobalt, tungsten, rare earth industry such as wet smelting of pressurized feeding of filter press,of course, also can be used for all kinds of acid, pulp, slurry, electrolyte, sewage and other medium transport. This series of pump not only can replace the III. Demonstration of model

|

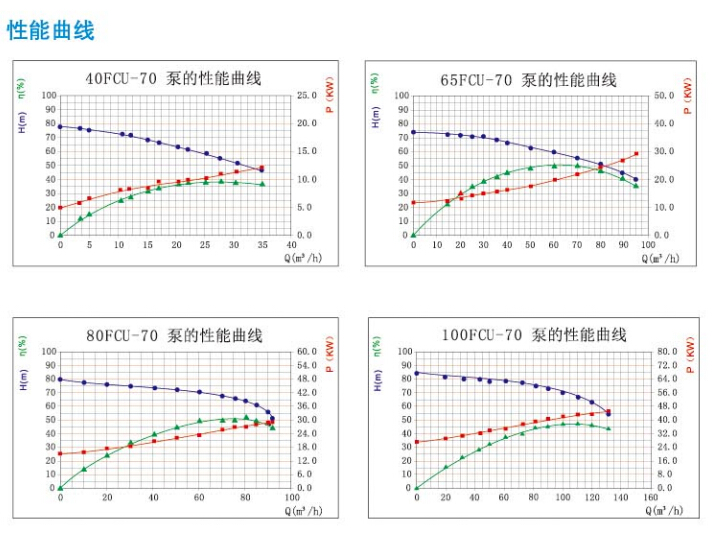

Performance curve

Performance parameters

| Model | Inlet*outlet | Quantity of flowm3/h | Quantity of flow m3/h | Head of deliverym | Head of delivery m | Click |

| 40FCU-70 | 40×40 | 12 | 3~20 | 70 | 80~11 | Details |

| 65FCU-70 | 65×50 | 25 | 8~40 | 70 | 82~11 | Details |

| 80FCU-70 | 80×65 | 50 | 15~80 | 70 | 79~9.5 | Details |

| 100FCU-70 | 100×80 | 100 | 35~110 | 70 | 81~11.5 | Details |

| 150FCU-70 | 150×125 | 150 | 50~220 | 70 | 79~9.5 | Details |

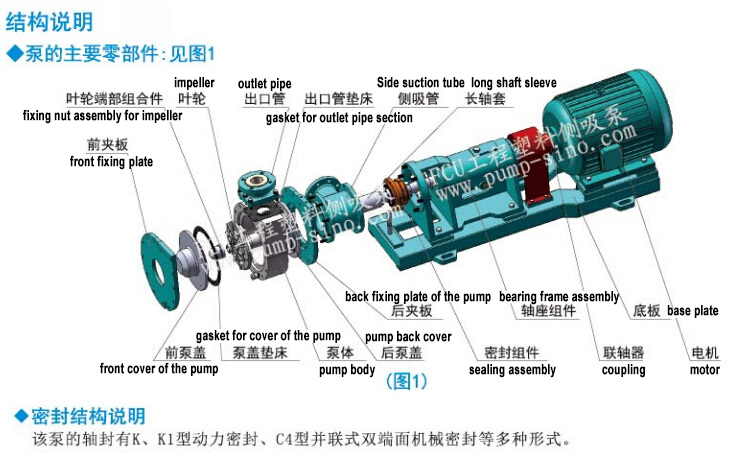

Structure description

(I) Main parts

Pre: FLU engineering plastic filter pump

Next: FTU ceramic plastic composite pump