FGU engineering plastic pipeline pump

|

I. General introduction The FGU engineering plastic pipeline pump is vertical,single-stage,single-suction,centrifugal pump. All the parts of the pump, which are in connection of the pumped liquid, are made of ultra-high molecular weight polyethylene (UHMWPE), which has excellent corrosion resistance, abrasion resistance (The best of the plastic) and anti-impact property. This series of pump can transport clean liquid and the corrosive medium containing a small amount of solid particles. The main features of the pumps are: II. Demonstration of model

|

Performance curve

.jpg)

Performance parameters

| Model | Inlet*outlet | Quantity of flowm3/h | Quantity of flow m3/h | Head of delivery m | Head of delivery m | Click |

| 40FGU-20 | 40×40 | 10 | 2.5~14 | 20 | 25~3.5 | Details |

| 50FGU-28 | 50×50 | 20 | 2.5~30 | 28 | 31~3.5 | Details |

| 65FGU-50 | 65×65 | 30 | 10~70 | 50 | 55~5 | Details |

| 80FGU-32 | 80×80 | 40 | 10~60 | 32 | 34~4 | Details |

| 100FGU-35 | 100×100 | 60 | 15~100 | 35 | 40~4 | Details |

| 100FGU-38 | 100×100 | 100 | 30~130 | 38 | 48~8 | Details |

| 150FGU-40 | 150×150 | 150 | 100~250 | 40 | 42~32 | Details |

| 150FGU-24 | 150×150 | 220 | 150~320 | 24 | 25~16 | Details |

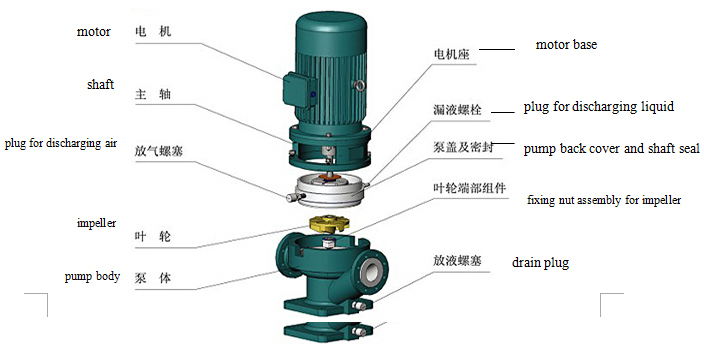

Structure description

(I) Main parts

(II) Seal structure

1. K type dynamic seal:

2. C1 type mechanical seal:

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)