FQU engineering plastic pump

|

I. General introduction The FQU series pumps are the corrosive resistant pumps, which are fully made of total engineering plastic. The structure of the pumps is very simple. The main features of the pumps are as below:

II. Application The FQU series pumps are widely used in chemical industry, non-ferrous metal industry (gold, silver, copper, lead, zinc, cobalt and nickel etc.), metallurgical industry (pickling, manganese industry),chemical fiber industry, titanium dioxide industry, rare earth industry, insecticide industry, phosphorous fertilizer industry, citric acid industry, paper industry, desulphation, food industry, water treatment and environment facilities. These pumps are the ideal pumps for pumping clean corrosive liquids. The working temperature of the pump is 80 ºC if material of the pump is FRPP (fiber reinforced polypropylene). The working temperature can be increased to 120 ºC if the material of the pump is PVDF.

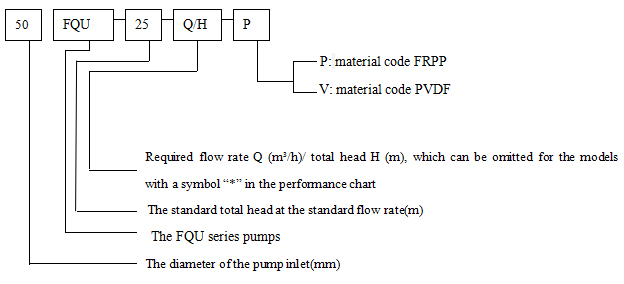

III. Demonstration of model

|

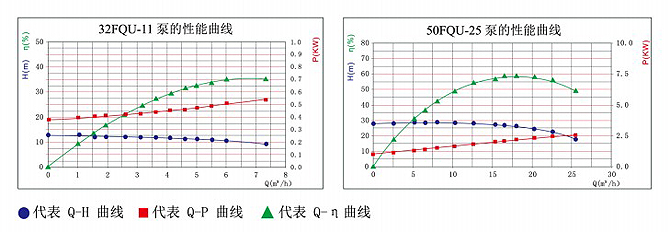

Performance curve

Performance parameters

|

Model |

Inlet×outlet |

Sealing type |

Impeller type |

Rated speed n=2900r/min |

||||||

|

Quantity of flow Q m3/h |

Head of delivery H |

NPSHr m |

1<γ≤1.2 |

1.2<γ≤1.4 |

||||||

|

Motor power and model |

||||||||||

|

kw |

Model |

kw |

Model |

|||||||

|

32FQU-11 |

32×25 |

C1 |

Standard |

*4 |

11 |

3.8 |

0.75 |

Y80M1-2 |

1.1 |

Y80M2-2 |

|

50FQU-25 |

50×40 |

C1 |

Standard |

5 |

29 |

3.8 |

2.2 |

Y90L-2 |

2.2 |

Y90L-2 |

|

10 |

28 |

3.9 |

2.2 |

Y90L-2 |

3 |

Y100L-2 |

||||

|

*18 |

25 |

4.0 |

3 |

Y100L-2 |

3 |

Y100L-2 |

||||

|

20 |

24 |

4.1 |

3 |

Y100L-2 |

4 |

Y112M-2 |

||||

|

A |

5 |

25 |

3.8 |

2.2 |

Y90L-2 |

2.2 |

Y90L-2 |

|||

|

10 |

24 |

3.8 |

2.2 |

Y90L-2 |

2.2 |

Y90L-2 |

||||

|

18 |

21 |

3.9 |

2.2 |

Y90L-2 |

3 |

Y100L-2 |

||||

|

20 |

19 |

4 |

3 |

Y100L-2 |

3 |

Y100L-2 |

||||

|

B |

5 |

20 |

3.6 |

2.2 |

Y90L-2 |

2.2 |

Y90L-2 |

|||

|

10 |

19 |

3.7 |

2.2 |

Y90L-2 |

2.2 |

Y90L-2 |

||||

|

18 |

16 |

3.8 |

2.2 |

Y90L-2 |

2.2 |

Y90L-2 |

||||

|

20 |

14 |

3.9 |

3 |

Y100L-2 |

3 |

Y100L-2 |

||||

|

C |

5 |

17 |

3.5 |

1.5 |

Y90S-2 |

1.5 |

Y90S-2 |

|||

|

10 |

16 |

3.6 |

1.5 |

Y90S-2 |

1.5 |

Y90S-2 |

||||

|

18 |

12 |

3.7 |

2.2 |

Y90L-2 |

2.2 |

Y90L-2 |

||||

|

20 |

10 |

3.8 |

2.2 |

Y90L-2 |

2.2 |

Y90L-2 |

||||

|

D |

5 |

14 |

3.4 |

1.5 |

Y90S-2 |

1.5 |

Y90S-2 |

|||

|

10 |

12 |

3.5 |

1.5 |

Y90S-2 |

1.5 |

Y90S-2 |

||||

|

18 |

9 |

3.6 |

2.2 |

Y90L-2 |

2.2 |

Y90L-2 |

||||

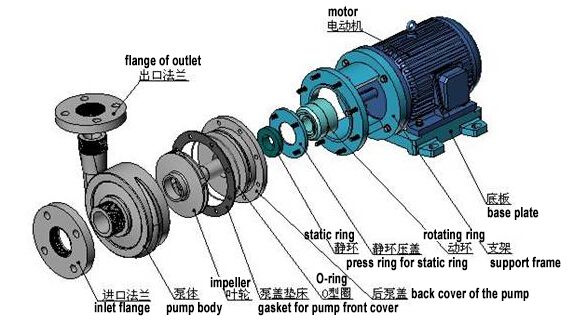

Structure description

Pre: FGU engineering plastic pipeline pump

Next: FPZJ water jet vacuum unit