FUH engineering plastic horizontal pump

|

I. General introduction The FUH pump is a horizontal single stage, single suction centrifugal pump with support frame. This series of pump is meticulously designed by using imported technology and converged the advantages of the best corrosion resistant pumps in China. The FUH series pumps won the National Awards of the New Product in 1995. II. Application The FUH series pumps are widely used for pumping liquids such as acid, alkaline, salts, oil, beverages and wine, whatever the liquids are clean or containing solid particles. In nonferrous metal industry, especially the pumps can be used for pumping various acids, electrolytes, sewages, ore magma or other serous materials in the hydro-metallurgical process for lead, zinc, gold, silver, copper, cobalt, tungsten and rare earth, for pumping diluted acid (pickling acid), parent liquid, hydrofluoric acid, fluoro-silicon acid, sea water and phosphoric acid in chemical fertilizer industry, for pumping different sewages in the food industry, electric planting factories, leather treatment factories, medicine industry, paper making industry, textile industry and electronic industry; for pumping sulphuric acid or hydrochloric acid in the iron and steel industry, used in the acid catalysed cleavage, settling, refrigeration, hydrologic, water washing, salts treatment process in titanium dioxide pigment industry, used in the fermentation, neutralizing, pressure filtration, water treatment in citric acid factories. The UHMWPE pumps are first selection of the alternatives of the imported pumps and other similar metal or non-metal pumps made in China. III. Demonstration of model

|

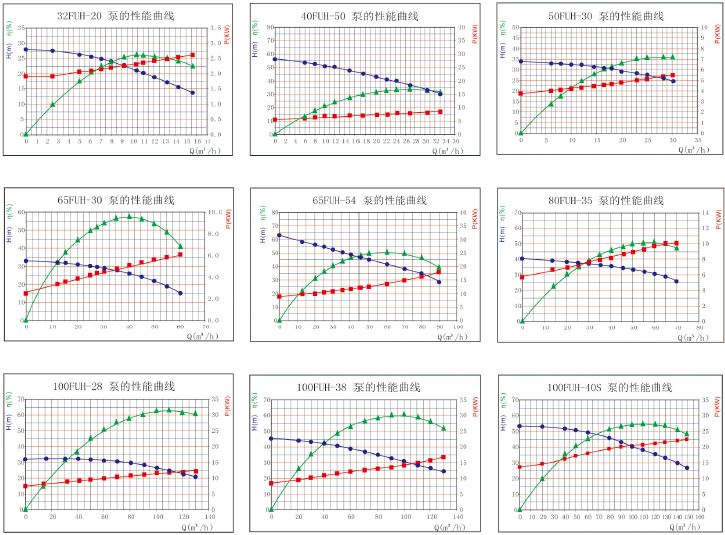

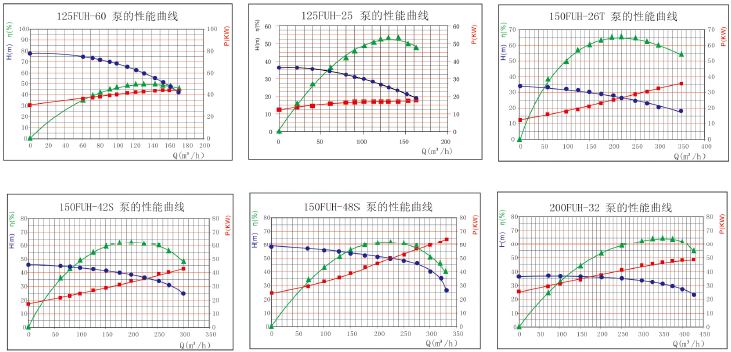

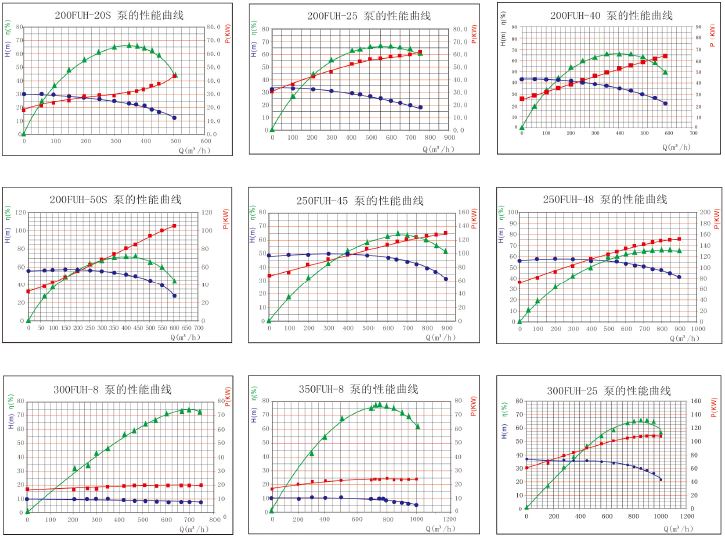

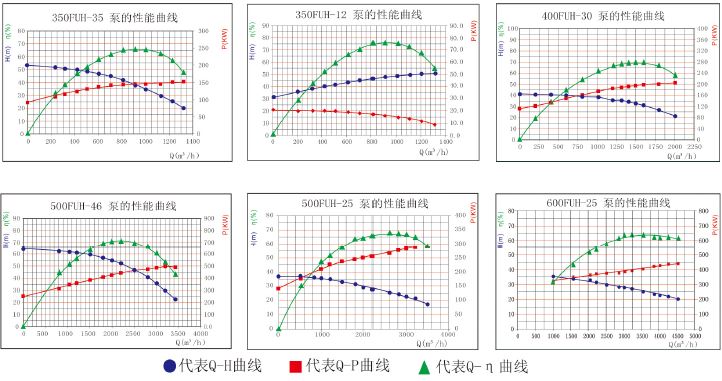

Performance curve

.jpg)

Performance parameters

| Model | Inlet*outlet |

Quantity of flowm3/h |

Quantity of flow m3/h |

Head of deliverym |

Head of delivery m | Click |

| 25FUH-30 | 25×25 | 10 | 2.5~14 | 20 | 25~3 | Details |

| 32FUH-20 | 32×25 | 10 | 2.5~14 | 20 | 25~3 | Details |

| 40FUH-50 | 40×32 | 12 | 3~20 | 50 | 64~8.5 | Details |

| 50FUH-30 | 50×40 | 20 | 2.5~30 | 30 | 33~4 | Details |

| 65FUH-30 | 65×50 | 25 | 7.5~45 | 30 | 33.5~3.5 | Details |

| 65FUH-54 | 65×50 | 30 | 10~60 | 54 | 63~3 | Details |

| 80FUH-35 | 80×65 | 40 | 15~60 | 35 | 36~4 | Details |

| 100FUH-38 | 100×80 | 60 | 25~100 | 38 | 40~4 | Details |

| 100FUH-28 | 100×80 | 80 | 30~130 | 28 | 30~3 | Details |

| 100FUH-40S | 100×80 | 100 | 30~130 | 40 | 60~4 | Details |

| 125FUH-60 | 125×100 | 120 | 40~160 | 60 | 69~6.5 | Details |

| 125FUH-25 | 125×100 | 130 | 40~160 | 25 | 32~2.5 | Details |

| 150FUH-42S | 150×125 | 150 | 80~250 | 42 | 43~9.5 | Details |

| 150FUH-26T | 150×125 | 220 | 100~320 | 26 | 35~3.5 | Details |

| 150FUH-48S | 150×125 | 250 | 100~300 | 48 | 56~14 | Details |

| 200FUH-32 | 200×150 | 350 | 165~420 | 32 | 35.5~8 | Details |

| 200FUH-20S | 200×150 | 400 | 165~500 | 20 | 30~3.5 | Details |

| 200FUH-25 | 200×200 | 500 | 270~700 | 25 | 32~6 | Details |

| 200FUH-25S | 200×200 | 500 | 270~700 | 25 | 32~6 | Details |

| 200FUH-40 | 200×150 | 300 | 135~500 | 40 | 44~10 | Details |

| 200FUH-50S | 200×150 | 450 | 200~550 | 50 | 55~12.5 | Details |

| 250FUH-45 |

250×200 |

650 | 335~900 | 45 | 48~10 | Details |

| 250FUH-45S | 250×200 | 650 | 335~900 | 45 | 48~10 | Details |

| 300FUH-8 | 300×300 | 700 | 300~750 | 8 | 9.5~7.5 | Details |

| 250FUH-48 |

250×200 |

800 | 265~900 | 48 | 56.5~18 | Details |

| 350FUH-8 | 350×300 | 900 | 400~1000 | 8 | 11~6.5 | Details |

| 300FUH-25 | 300×300 | 950 | 439~1000 | 25 | 38~7 | Details |

| 350FUH-12 | 350×350 | 1200 | 600~1200 | 12 | 18~9 | Details |

| 350FUH-35 | 350×300 | 1000 | 610~1300 | 35 | 45~7 | Details |

| 400FUH-30 | 400×350 | 1500 | 920~2000 | 30 | 40~7 | Details |

| 500FUH-25 | 500×400 | 2600 | 2000~3500 | 25 | 34~18 | Details |

| 500FUH-46 | 500×400 | 2500 | 1500~3400 | 46 | 59~6 | Details |

| 600FUH-25 |

600×500

|

3500

|

3200~4500

|

25

|

32~18

|

Structure description

Main parts (refers to picture 1)

.jpg)

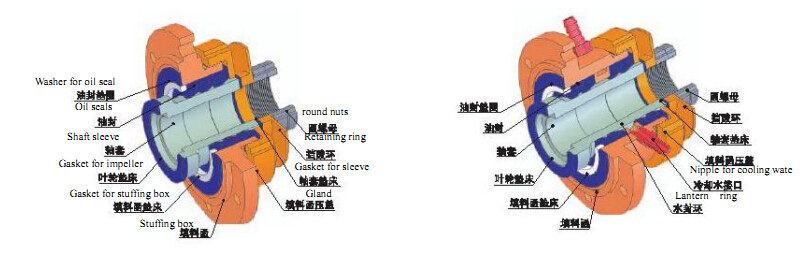

Comparison of the different types of seals

|

Type of Seal |

Features |

Application |

|

K Type Dynamic Seal |

Using 2-3 oil seal rings made of fluoro-rubber as seal parts. It is simple, reliable and cheap. It is not allowed to empty run the pump for more than 5 minutes. |

It is a general purpose seal used for clean corrosive liquids or the slurry and sewages containing ≤5% solid particles (Except alkaline solution) |

|

K1 Type Dynamic Seal |

As same as K type, but empty run is allowable because there is cooling water supply. Its service life is longer than K type. |

As same as K type |

|

C1 Type Standard Mechanical Seal |

Use WB2 type standard mechanical seal. There are different materials of the seal rings for selection |

Suitable for clean liquids. Also can be used for the liquids containing trace solid by using the seal rings made of hard materials. |

|

C2 Type Non-standard Mechanical Seal |

This is an internal self-cooling mechanical seal. Both the rotating ring and stationary ring are made of SiC. Cooling water is not required. Maximum empty running time is 20 min. It is expensive, but its service life is longer than the T and T1 types. |

It is suitable for the corrosive liquids containing solid particles between 5%-35%. |

|

C3 Type Non-standard Mechanical Seal |

As same as above, but with cooling water supply. To empty run the pump for more 20 minutes is allowable. Its service life is longer than C2 type. |

As same as C2 type. |

|

C3BType Double Mechanical Seal |

It has reliable sealing property, and it can extend service life. |

The same as above. |

|

C4 Type Double |

It has compact structure, high reliability, long service life. It is convenient for installation and maintenance. |

Suitable for clear liquid or slurry with high solid content (5%¡Üsolid content¡Ü35%), and sewage containing impurities, and other corrosive media, it has wide range of application. |

|

T Type Packing Seal |

Use expanded Teflon packing. Can stand corrosion and erosion. It is simple and reliable. |

Suitable for the corrosive liquids containing big amount of solid particles (25%-40%) or the sewages with big amount of foreign matters. |

|

T1 type Packing Seal |

As same as T type, but with cooling water supply. Its service life is longer than that of T type. |

As same as T type. |

Note: The cooling water for seals above must be clean water. the yield of water50~80kg/h,pressure 0.5~1.0kg/cm2

|

T2 balanced type Packing Seal |

Combined packing and seal, corrosion and wear resistance, simple structure, no leakage, cooling water is required, water pressure required between 1.5 ~ 4 kg/cm2 clean running water. |

Suitable for the corrosive liquids containing large amounts of solid particles or easy crystallization medium, and medium are allowed a small amount of cooling water |

Note: The cooling water for seals above must be clean water. Pressure1.5~4kg/cm2

K, K1 TYPE DYNAMIC SEAL: FIG. 2 & FIG. 3

This is a dynamic seal using latest imported technology. It is composed of expeller on the back of impeller and rubber seal rings. When the pump is in operation, the centrifugal force, which is created by the expeller, maintains a negative pressure in the annular seal space, so there is no any leakage. At same time, the lips of the rubber seals is not touching the sleeve, so there is no any erosion between the rubber seals and sleeve. When the pump is stopped, the pressure in the stuffing box becomes positive. It presses the lips of the rubber seals touching the sleeve closely, so the gap between the rubber seals and sleeve is sealed up. If the mixing of the cooling water with the medium is allowable, the K1 type is recommended, which possesses cooling water nipple, so the cooling is more effective (See fig. 2). The rubber seal rings are made of fluoro-rubber (Viton). K & K1 type seals are suitable for handling the liquids containing high percentage of solid particles.

(The cooling water for K1 type seal must be clean water)

.jpg)

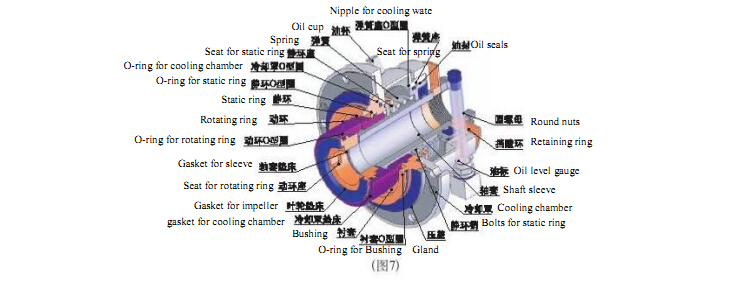

C2 TYPE NON-STANDARD MECHANICAL SEAL: FIG. 6

this is an internal non-standard mechanical seal designed by Yixin Engineering Plastic Pump Factory. No cooling

water is required by using heat conductive oil and air cooling system. Both the static ring and rotating ring

are made of SiC. So this kind of the seal is suitable for pumping corrosive liquids containing big amount of

solid particles. (The heat conductive oil is 25# transformer oil)

.jpg)

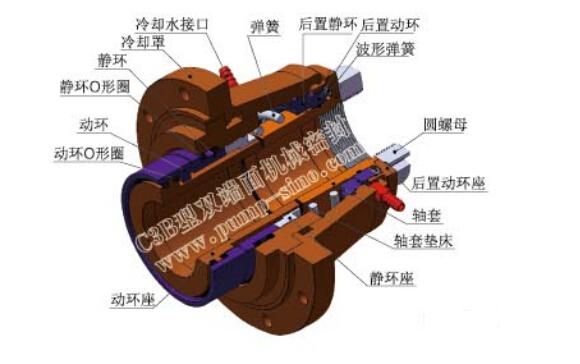

C3B type double end facemechanical seal:

My company design this built-in type non-standard mechanical seal on the basis of C3 mechanical seal.The original rear cooling water oil seal was changed to the relatively independent mechanical seal structure with the primary seal.When the cooling water pressure in excess of the prescribed value,the rear of the mechanical seal can automatic pressure relief to ensure the primary seal in allowing end face specific pressure within the scope of work and reduce the abrasion of the ring and static ring.Its life is longer than C3 type mechanical seal.The seal can be used to transport corrosive liquids which contain large amounts of particles.

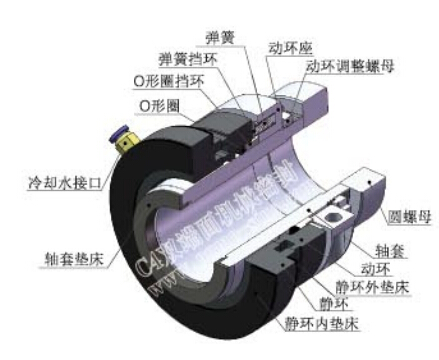

C4 type double end face mechanical seal:

My company design the latest parallel type double end face mechanical seal with mounted outside and multiple springs structure.Its biggest characteristic is the ring and static ring have grooves corresponding to the place to form two parallel sealing surface and at the same time can transport cooling water.Ring and static ring is made of silicon carbide,only silicon carbide and fluorine rubber contact medium and cooling water,so it is resistant to corrosion and wear and have a more excellent performance.In addition,the main parts of the seal are mounted outside so we can stop the pump to check the status of sealing surface at any time and it's convenient to maintain.The seal has simple and compact structure, high reliability, long service life and can transport corrosive liquids which contain a large amount of solid particles(Note: the cooling water is clean water).

Pre: None

Next: FDU engineering plastic low-speed slurry pump

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(1).jpg)