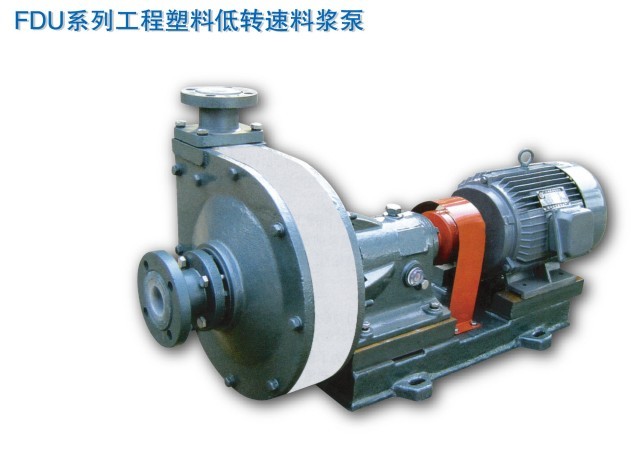

FDU engineering plastic low-speed slurry pump

|

I.General introduction The FDU series pump is developed on the basis of our FUH pump technology absorbing other advantages of the latest low speed pump in China. Compare with the FUH series pump, the advantages of the FDU series pump are: 1、The pump front cover and back cover are separated from the pump body. This design makes the maintenance much easier. This design also reduces the maintenance cost when you have to replace the eroded parts. All the wet parts of the FDU series pump are made of ultra-high molecular weight polyethylene (UHMWPE), which has excellent corrosion resistance, erosion resistance (best in plastic) and anti-impact property. There are different type of seals for selection, such as mechanical seal, dynamic seal and packing seal, which are able to meet for pumping different kind of acid or alkaline. The FDU pumps display its excellent properties when pumping hydro-fluoric acid, phosphoric acid, mixed acid, electrolytes, hydrochloride acid, diluted sulphur acid, concentrated alkaline, which contain high percentage of solid particles. The working temperature of the FDU pumps is -50〜100ºC. This temperature can be increased to 120 ºC if the impeller and the casing of the pump are replaced with the ones made of PVDF or CPE. The FDU series pumps are horizontal single stage, single suction centrifugal pump with bearing frame. II.Application The FDU series pumps are mainly used for pumping different kind of liquids such as acid, alkaline, salts, oil, beverages and wine. They are widely used in chemical industry for pumping acid, alkaline, salts, oil and different kind of liquids, whatever the liquids are clean or containing solid particles; used in nonferrous metal industry, especially in the factories producing lead, zinc, gold, silver, copper, cobalt, tungsten and rare earth etc for pumping various acids, ore magma, slurry (for pumping slurry to filter press) electrolytes, sewages; used in fertilizer industry for pumping diluted sulphur acid, parent liquid, hydrofluoric acid, fluoro-silicon acid, sea water and phosphoric acid slurry; used for water treatment or environment facilities for pumping different kind of sewages(sewage from food industry, electroplating industry, leather industry, medicine industry, paper making industry, textile plant and electronic industry etc.); used in the acid catalysed cleavage, settling, refrigeration, hydrologic, water washing, salts treatment process in titanium dioxide pigment industry; used in acid station in the chemical fiber industry; used in the fermentation, neutralizing, pressure filtration, water treatment in citric acid factories; used in manganese industry. The UHMWPE pumps are first selection of the alternatives of the imported pumps and other similar metal or non-metal pumps made in China. III.Demonstration of model

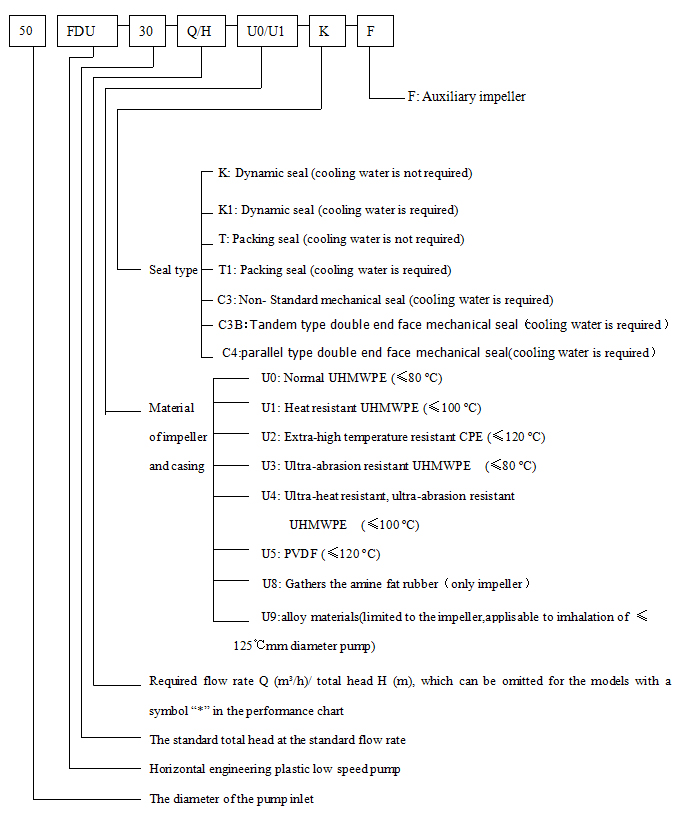

|

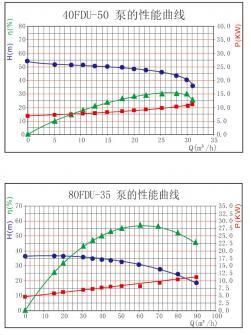

Performance curve

.jpg)

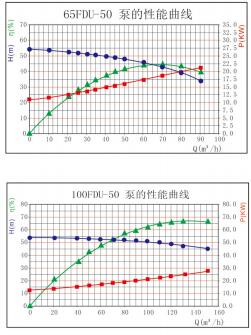

Performance parameters

Performance parameters

| Model | Inlet*outlet | Quantity of flowm3/h | Quantity of flow m3/h | Head of delivery m | Head of delivery m | Click |

| 40FDU-50 | 40×32 | 15 | 3.3~20 | 50 | 52~20.4 | Details |

| 50FDU-30 | 50×40 | 20 | 3.3~20 | 30 | 37~6.2 | Details |

| 65FDU-50 | 65×50 | 30 | 13.5~70 | 50 | 57~9 | Details |

| 80FDU-35 | 80×65 | 40 | 13.3~60 | 35 | 41.5~6.6 | Details |

| 100FDU-38 | 100×80 | 60 | 14~90 | 38 | 45~10 | Details |

| 100FDU-50 | 100×80 | 100 | 47.5~14 | 50 | 57~6 | Details |

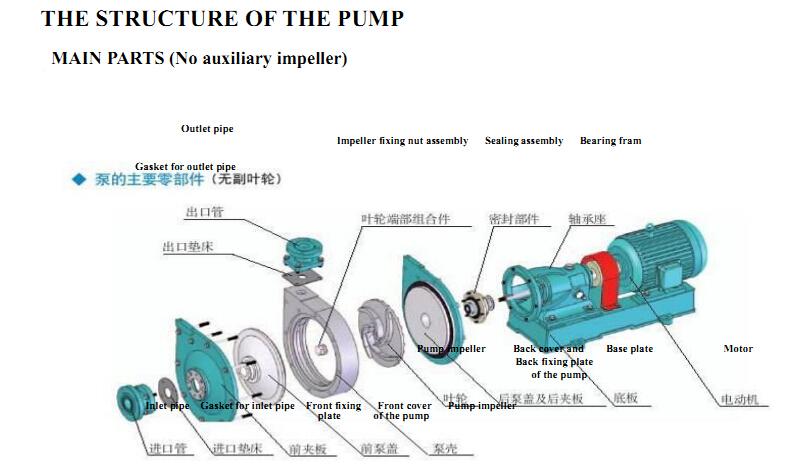

Structure description

FDU structure

.jpg)

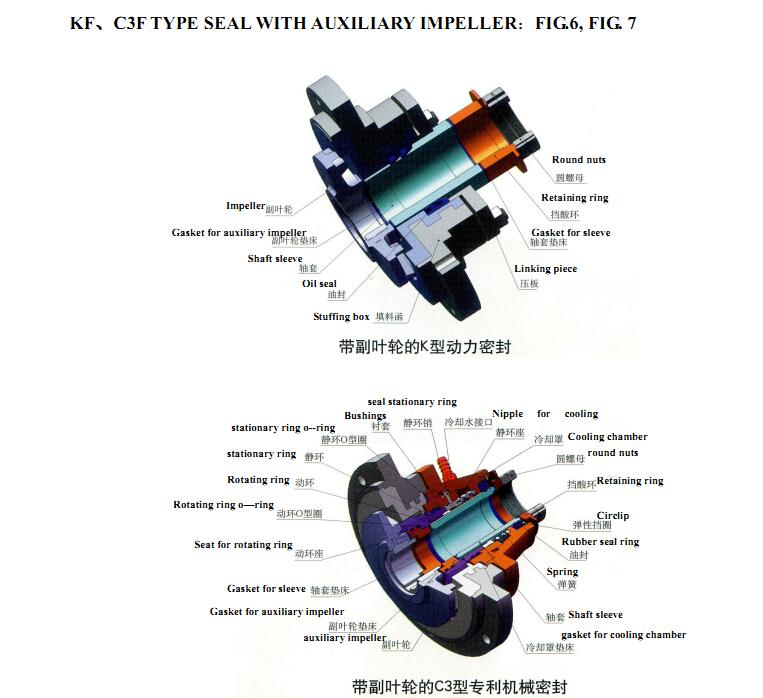

This seal which add auxiliary impeller is made based on K-type dynamic seal, K1-type dynamic seal with the cooling water, C3-type non-standard mechanical seal and T-type packing seal mentioned above, due to the presence of auxiliary impeller, so that the pressure on the front of these seals is small, or somewhat negative, especially when the pump’s flow is small or even pressureout, the wear of seals can be reduced to improve the life of seals; at the same time, with the existence of auxiliary impeller, a higher solid content in the transportation of liquid, this seals can effectively prevent the solid particles into the stuffing box and improve the life of seals (Fig. 6 as KF-type dynamic seal with a auxiliary impeller, Fig. 7 as C3F-type non-standard mechanical seal with a auxiliary impeller).

The pumps equipped with the seals of this type, are for handling the liquids containing high percentage of solid particles, and particularly for supporting the use of filter press, the life of these seals are much longer than those wtinout auxiliary impeller.

Pre: FUH engineering plastic horizontal pump

Next: FLU engineering plastic filter pump