FYUB engineering plastic cantilever type submerged pump

|

I. General introduction

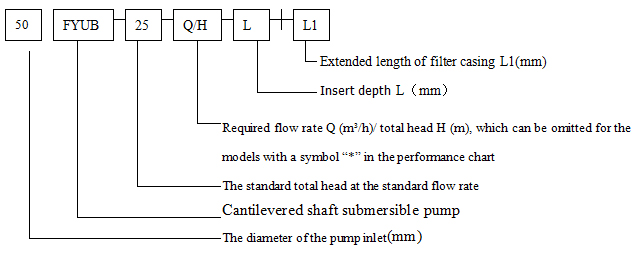

II. Demonstration of model

|

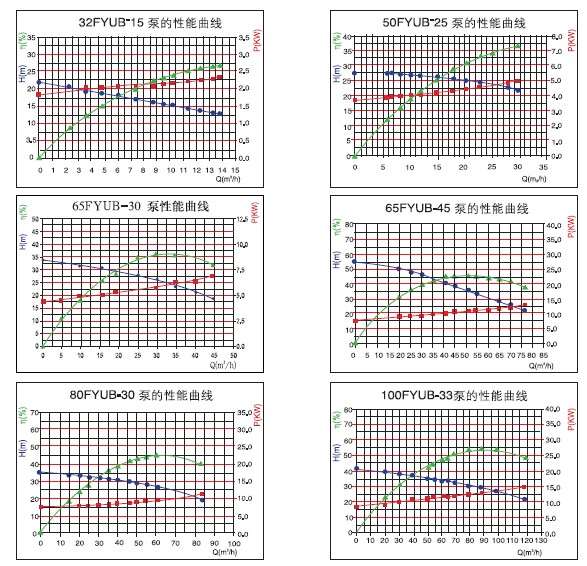

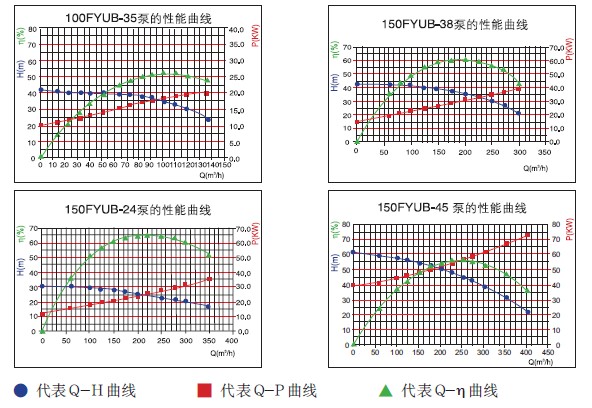

Performance curve

Performance parameters

| Model | Inlet*outlet | Quantity of flowm3/h | Quantity of flow m3/h | Head of delivery m | Head of delivery m |

Submerged depthL |

Click |

| 32FYUB-15 | 32×25 | 10 | 5~15 | 15 | 20~5 | 500 750 1000 |

Details |

| 50FYUB-25 | 50×40 | 20 | 5~30 | 25 | 27~2.5 | Details | |

| 65FYUB-30 | 65×65 | 25 | 7.5~45 | 28 | 30~2.5 | Details | |

| 65FYUB-45 | 65×65 | 30 | 10~70 | 45 | 55~5.5 | Details | |

| 80FYUB-30 | 80×65 | 40 | 12.5~70 | 30 | 31.5~2.5 | Details | |

| 100FYUB-33 | 100×80 | 60 | 15~100 | 33 | 36~3.5 | Details | |

| 100FYUB-35 | 100×80 | 100 | 25~130 | 35 | 37~4.5 | Details | |

| 150FYUB-38 | 150×125 | 150 | 65~250 | 38 | 40~9 | Details | |

| 150FYUB-24 | 150×125 | 220 | 100~300 | 24 | 35~4 | Details | |

| 150FYUB-45 | 150×125 | 250 | 100~400 | 45 | 54~6.5 |

750 |

Details |

| 200FYUB-20 | 200×150 | 400 | 200~500 | 20 | 28~3.5 |

|

Details |

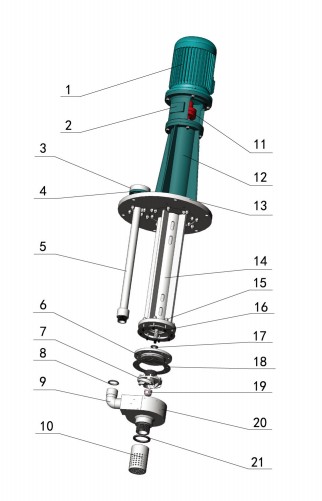

Structure description

1.Structural type is vertical, single-stage and single suction centrifugal pump.

2.Adopts high-rigidity cantilever spindle, without auxiliary bearing structure.

3.Main parts (refers to picture 1)

1) Motor 2) Motor base 3) Discharge flange 4)Upper and lower bearing 5) Outlet pipe 6) Pump cover 7) Impeller

8) Outlet pipe bed 9) Bend 10) Filter casing 11) Coupling 12) Bearing base 13) Base plate 14)Joint pipe

15) Pump bolt 16)Plastic coated spindle 17)Impeller equilizing bed 18) Pump cover bed 19)Impeller end assembly 20) Pump body 21) Filter casing bed

4. Impeller, pump body and other flow passage components are manufactured with ultra-high molecular weight polyethylene (UHPE), other parts are manufactured with corrosion resistant PP and FRPP.

5.Direction of rotation: according to arrow pointing direction.

Pre: FTU ceramic plastic composite pump

Next: FYUC engineering plastic low-speed cantilever slurry submerged pump

.jpg)

.jpg)