FYUC engineering plastic low-speed cantilever slurry submerged pump

|

I. General introduction The FYUC series of engineering plastics low-speed cantilever residue slurry pump is developed on the basis of successful experience and mature technologies of absorbing the development of high speed serial FYUB cantilever liquid FDU pump and low-speed serial horizontal pump.The series of flow components pump adopted the ultra-high mol ecular weight polyethylene (UHMWPE) production, has excellent anti-corrosion, anti-abrasive and anti-impact properties; Meanwhile, the application of axis cantilever structure and the abolition of the lower part of the auxiliary supports, thorough settled the difficulties of the lower part of the auxiliary can not support cooling water and lubrication of non anti-abrasion etc.Due to the low speed, the pump gains better anti-abrasion property and stable operation. Particularly applicable to the corrosive media that contains high volume solidity particles without cooling water. (including the weight of solid particle concentrations ≤ 20% Solid particle diameter less than 1.0mm), the application of the pump ≤ 80 ° C.

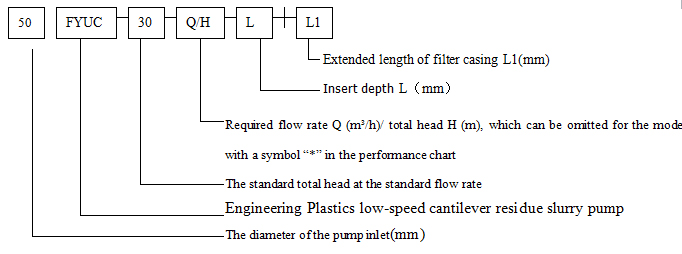

II. Demonstration of model

|

Performance curve

.jpg)

.jpg)

Performance parameters

| Model | Inlet*outlet | Quantity of flowm3/h | Quantity of flow m3/h | Head of delivery m | Head of delivery m | Click |

| 40FYUC-50 | 40×40 | 15 | 3~25 | 46 | 48~8 | Details |

| 50FYUC-30 | 50×40 | 20 | 3.3~30 | 30 | 32~6.2 | Details |

| 65FYUC-50 | 65×65 | 30 | 13.5~70 | 50 | 52~9 | Details |

| 80FYUC-35 | 80×65 | 40 | 13.3~60 | 35 | 37~6.6 | Details |

| 100FYUC-50 | 100×80 | 100 | 47.5~140 | 50 | 52~6 | Details |

| 150FYUC-38 | 150×125 | 150 | 65~250 | 38 | 40~9 | Details |

| 150FYUC-24 | 150×125 | 220 | 100~300 | 24 | 35~4 | Details |

| 150FYUC-45 | 150×125 | 250 | 100~400 | 45 | 54~6.5 | Details |

| 200FYUC-20 | 200×150 | 400 | 200~500 | 20 | 28~3.5 | Details |

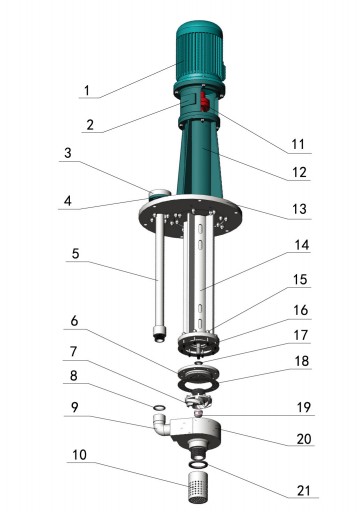

Structure description

1. Structural type is vertical, single-stage and single suction centrifugal pump.

2. Adopts high-rigidity cantilever spindle, without auxiliary bearing structure.

3. Main parts:

1) Motor 2) Motor base 3) Discharge flange 4)Upper and lower bearing 5) Outlet pipe 6) Pump cover 7) Impeller

8) Outlet pipe bed 9) Bend 10) Filter casing 11) Coupling 12) Bearing base 13) Base plate 14)Joint pipe

15) Pump bolt 16)Plastic coated spindle 17)Impeller equilizing bed 18) Pump cover bed 19)Impeller end assembly

20) Pump body 21) Filter casing bed

4. Impeller, pump body and other flow passage components are manufactured with ultra-high molecular weight polyethylene (UHPE), other parts are manufactured with corrosion resistant PP and FRPP.

5. Direction of rotation: according to arrow pointing direction.

Pre: FYUB engineering plastic cantilever type submerged pump

Next: FZU engineering plastic vertical self-priming pump